Due to climate change there is a significant increase in the risk of buildings overheating worldwide. The building industry face the complex challenge of creating sustainable buildings that balance health, comfort, and energy efficiency. This involves adapting to improved building fabrics, adhering to strict regulations, and meeting the diverse needs of occupants.

Although climate change is essentially the main driver behind the temperature increase, one key reason for overheating in buildings is the improved building fabric standards, which are designed keep the building warm in winter, but trap heat inside during warmer periods.

It is a complex issue that is affected by a wide range of issues, such as increased amounts of glazing on modern buildings which allow more solar gains, or lightweight constructions which are prone to large fluctuations in temperature.

The challenges of modern building design are intensified by the higher temperatures from climate change. Many buildings today are designed without adequate passive cooling solutions, often due to environmental and security concerns.

Homes with unshaded, double-glazed windows will feel the heat on warm days.

Increased levels of insulation, airtightness and large areas of glazing are some of the design factors which result in retained heat.

Mechanical services and electrical appliances all contribute to heat gain in a dwelling. This, combined with heat from activities like cooking can raise indoor temperatures.

The presence of more occupants in a home can contribute to overheating as each person naturally emits body heat and moisture.

To address this pressing issue, regulatory bodies have implemented new standards to ensure residential buildings maintain comfortable temperatures. Approved Document O in England and its counterparts in Wales and Scotland mandate compliance with thermal comfort regulations.

Approved Document O (2021 edition – England) was released in December 2021 and came into force for all Building Regulations building notices, full plans applications and initial notices for residential buildings submitted in England from 15 June 2022.

Approved Document O (2022 edition – Wales) was released in May 2022 and came into force for all Building Regulations building notices, full plans applications and initial notices for residential buildings submitted in Wales from 23 November 2022.

Standard 3.28 of the Scottish Building Standards Domestic Technical Handbook (December 2022 edition) was released in June 2022 and came into force for all residential Building Warrant applications submitted in Scotland from 01 February 2023.

Excessive heat in homes is not solely a result of environmental factors but also of design, making thermal modeling crucial. In addition to core design features, implementing certain solutions within the dwelling can create a win-win situation. For instance, low-energy lighting not only reduces energy usage but also helps in lowering internal heat gains.

Key Design Considerations for Overheating

A good indoor climate is a balance between health, energy efficiency, and comfort:

Combining ventilation with active cooling can offer a low carbon solution to overheating issues in residential properties and can be designed in conjunction with dynamic thermal modelling.

In most instances, a mechanical ventilation system such as MEV (Central Extract System) or more likely MVHR (Heat Recovery) forms the base of the strategy for overheating. This can then be adapted accordingly to ensure compliance with best practice guidance (CIBSE TM59).

Zehnder offers various options, ranging from standalone solutions to integrated strategies, aimed at mitigating overheating whilst also balancing health, energy efficiency, and providing a comfortable indoor environment.

LPID100 Low Profile Induct Fan

Acoustically treated inline extractor fans located in habitable rooms provide additional ventilation up to 4 ACH in lieu of openable windows.

Quiet in operation and ideal for running at night! Can be used in conjunction with MEV and MVHR mechanical systems.

Zehnder ComfoAir Q

Increased extract and supply rates (typically to around 2.5ACH) to provide purge requirements without the need for additional solutions.

Radial ducting ensures a balanced system and reduces noise and leakage to maintain lower running speeds

True summer by-pass and passive cooling

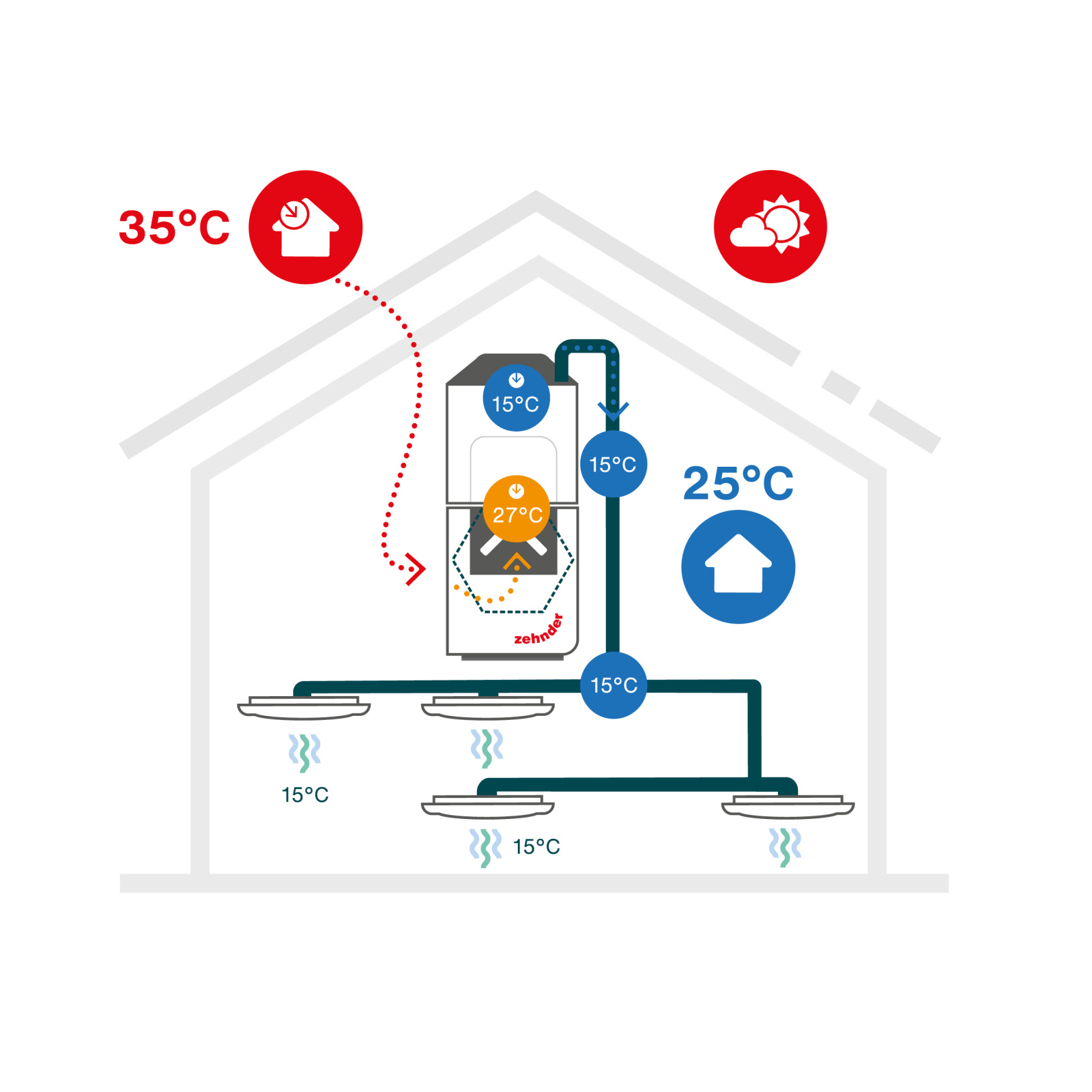

Modulating bypass within MVHR system constantly aims to improve the internal comfort temperature/humidity by allowing full/partial/no heat recovery depending on conditions.

Constant volume motors ensure ventilation rates are met and help overcome increased pressure drops.

Passive cooling can be activated based on external conditions that can help maximise comfort in warmer months by automatically boosting supply air rates

Zehnder ComfoTube Therm

Innovative Zehnder ComfoTube Therm ducting solutions ensure continuously insulated air distribution, so the living space is cooled and heated in an energy efficient manner.

Durable, whilst maintaining its flexible properties.

Zehnder ComfoFond

Working in conjunction with the MVHR system, sealed ground loops and a water to air heat exchanger provide pre-heating in the winter and pre-cooling in the summer on the supply/intake air.

Zehnder ComfoClime & Enthalpy

Working in conjunction with the MVHR system, this provides 1.5KW active air temperation and dehumidification via refrigerant cycle. Enthalpy MVHR cell passively reduces humidity of incoming fresh air under favourable internal/external conditions.

Zehnder ComfoPost

Works in conjunction with a centralised chiller system or reversible heat pump to provide 1.88-5.64KW of cooling capacity via the supply air of a constant volume MVHR system with Enthalpy cell.

Don't wait for overheating to become a problem, act now to beat the heat and mitigate overheating in buildings. Whether you're a developer, consultant, social housing provider, or homeowner, we're here to help. Ensure regulatory compliance, optimise designs, enhance livability, and create comfortable spaces with our expert solutions. Partner with us for a safer, more comfortable future.

General Request

Contact FormOffer Request

Contact FormOrder Request

Contact FormGeneral Request

+44 (0) 1276 605 800Technical Support

+44 (0) 1276 605 800